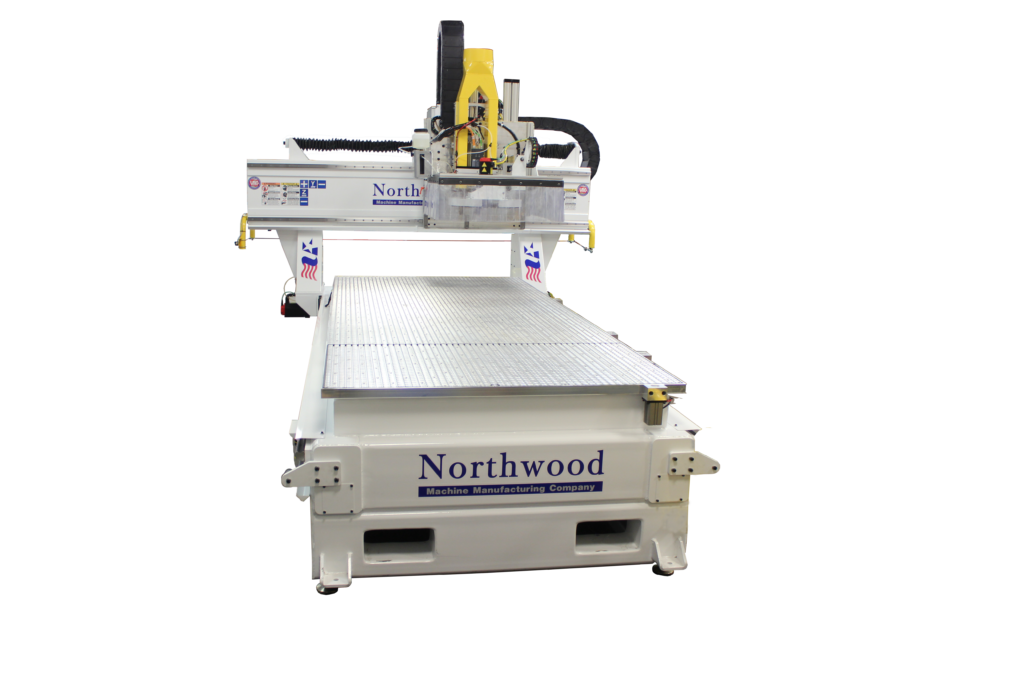

Designed for longevity, the Iron Horse Traveling Gantry Series combines the legendary routing,

sawing, milling, and drilling performance you expect from Northwood Machine – in a traveling

gantry format.

This American Made Iron Horse features Fanuc Precision CNC Controls, Servo Motors, and a

Fanuc push-button panel with 21.5” widescreen operator touch panel.

18 to 24 Horsepower Spindles crank up to 24,000 RPM for precise cutting – and with the option

of Dual-Head manufacturing process – you’ll enjoy increased throughput by up to 200%.

Twelve or Twenty position travel-along tool changers save additional time by allowing

background drilling during tool changeovers.

A 9, 21 or 35 line spindle multi-drill unit makes quick work for drilling different size holes or

multiple holes at the same time.

Optional features include: automatic labeling, loading and unloading. Worktables both 4ft and 5ft

wide in single zone up to 60ft long or split work zones allow for loading and unloading while

cutting on the adjacent work zone.

A phenolic or cast aluminum vacuum matrix table is used for even vacuum hold down and

accepts industry standard vacuum cups or pods. And the 1.25” diameter steel location pins

accurately locate sheets – every time.

As with every Northwood product, onsite installation, training, lifetime factory remote diagnostics

and tech support is always included, maintenance agreements not required. And with the

integrated Northwood Live analytics dashboard, real-time performance and efficiency monitoring

keeps your business running ahead of the competition. If you’re ready to go to the next level,

look no further.

Choose The Iron Horse Traveling Gantry Series from Northwood Machine.