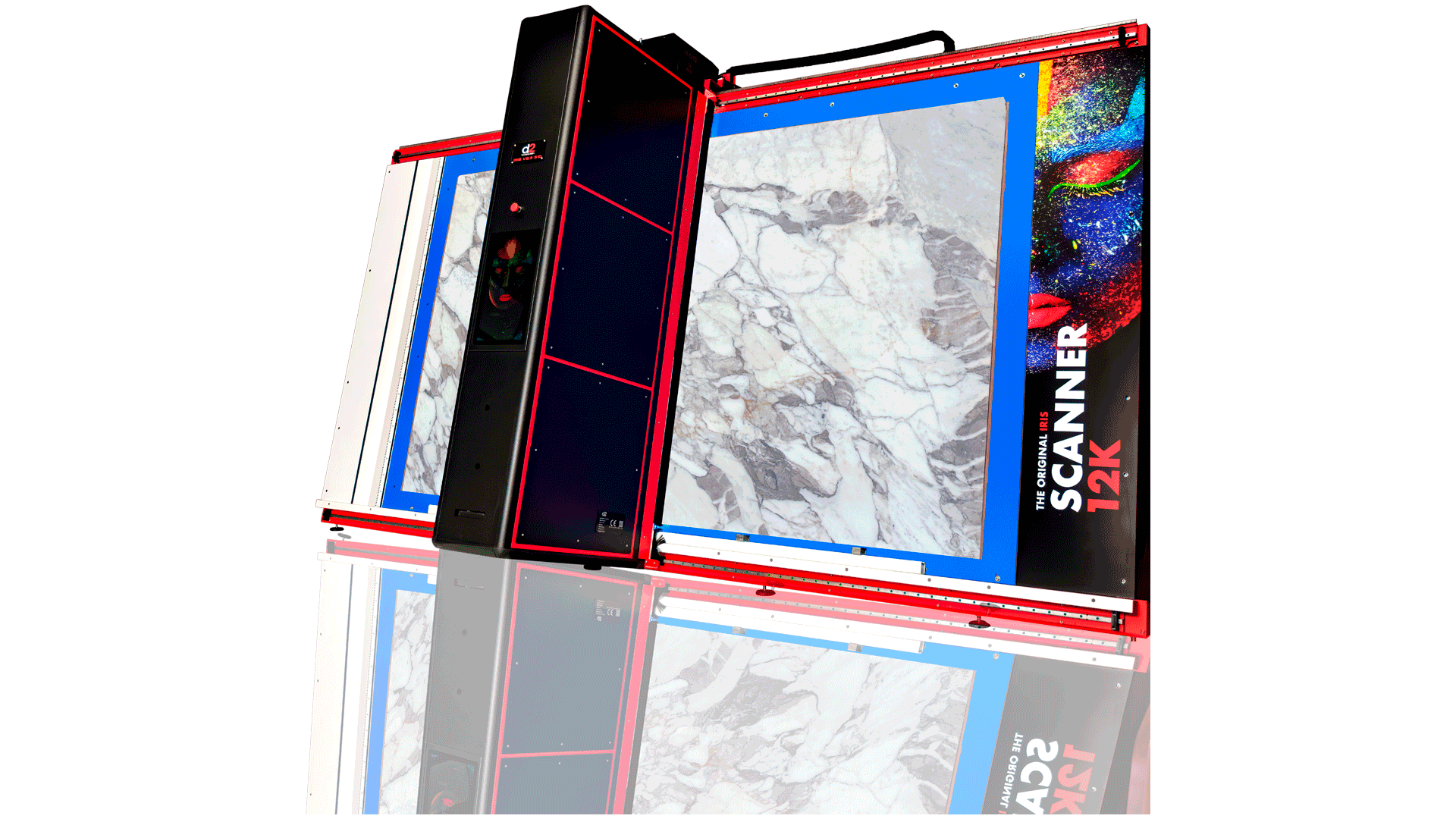

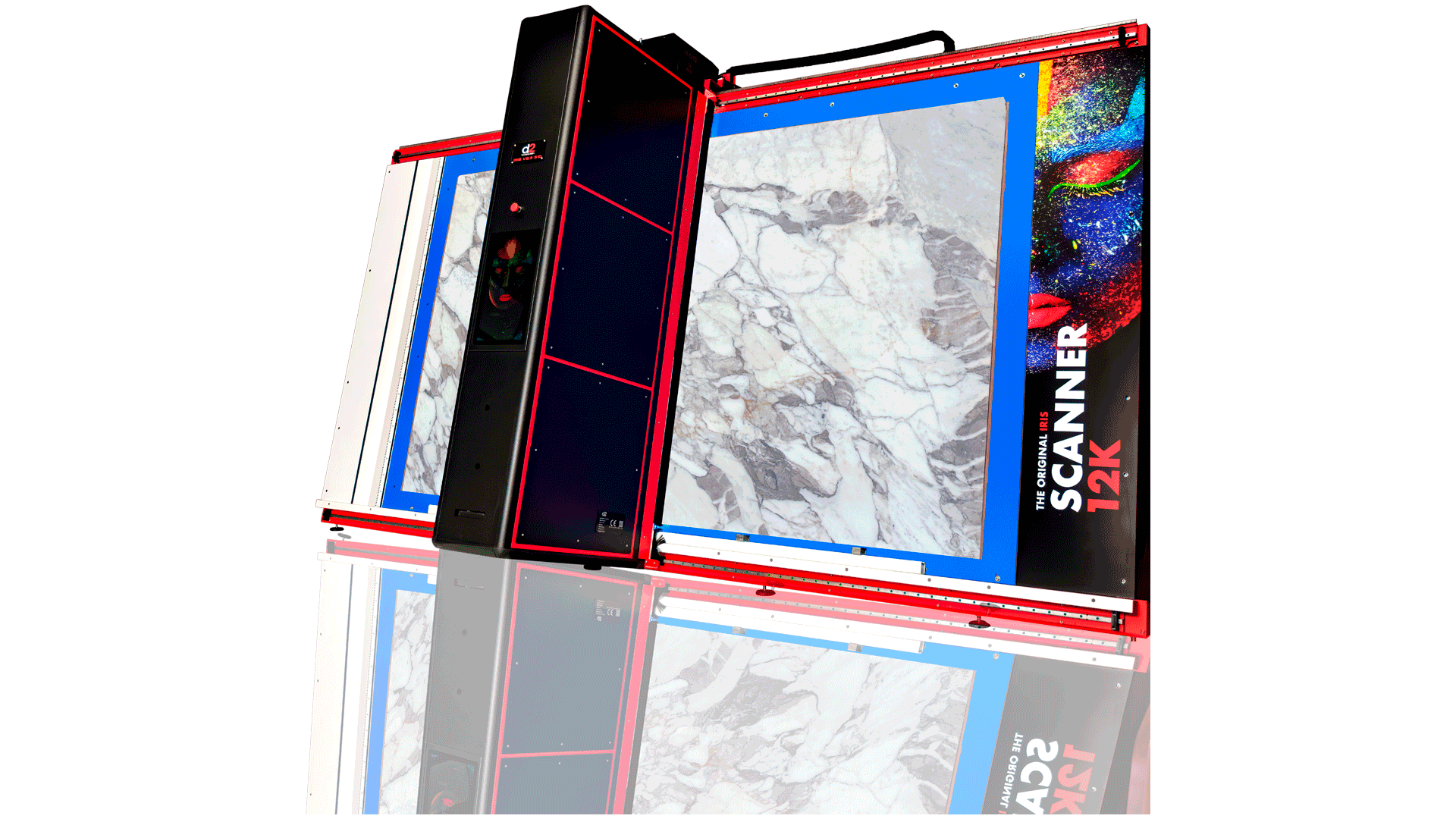

D2 Iris Scanner for Stone Fabricators

High-Precision Slab Imaging in 12K Resolution

The D2 Iris Scanner is an advanced digital imaging system engineered specifically for the needs of stone fabricators. Offering true 12K resolution and a compact vertical design, this cutting-edge slab scanner captures natural stone slabs in lifelike detail, enabling enhanced inventory control, precise vein matching, and elevated client presentation.

Whether you’re managing a high-volume fabrication shop or a boutique operation with a focus on premium materials, the D2 Iris Scanner helps bring accuracy, speed, and clarity to every stage of your process—from intake and layout to sales and installation.

- 12K Resolution

- Compact Footprint

- Inventory Management

Key Features

Video

Features & Benefits

Unparalleled Image Quality

At the heart of the D2 Iris Scanner is its ultra-high-definition 12K sensor, which delivers detailed slab captures without color distortion, reflection, or glare. This level of resolution allows fabricators to visualize even the subtlest veining, natural imperfections, and texture variations—creating a more reliable and confident path from material selection to final product.

-

True 12K resolution for razor-sharp imaging

-

Vertical orientation reduces ambient lighting interference

-

Displays full slabs as they appear in real life—no manual photo editing required

Artificial Intelligence Meets Stone Imaging

The D2 Iris Scanner is more than a high-resolution camera—it’s part of a larger AI-driven ecosystem. When paired with D2 Smart Targets and Northwood’s cutting technology, AI automatically evaluates slab dimensions, identifies defects, and recommends optimal cut paths based on material type and project specs. This dramatically reduces programming time, improves cut consistency, and minimizes human error—making your shop faster, smarter, and more efficient.

See the AI in action: Check out our short video showing how the D2 Iris Scanner integrates with AI for smarter slab processing.

Watch the video on YouTube →

Optimized Workflow and Digital Inventory Management

The scanner comes fully integrated with Match software, which offers robust digital inventory capabilities. Each slab scan is automatically associated with essential data like material name, type, thickness, and dimensions. Using barcode scanning, the system ensures slab status is updated in real time—whether it’s incoming, allocated to a project, or marked as used at the saw.

-

Barcode-based slab tracking

-

Real-time inventory updates

-

Searchable database with image preview

-

Easy digital access to slab dimensions and characteristics

By digitizing your material handling, your team can make quicker, more accurate decisions—and reduce costly errors caused by manual recordkeeping or incomplete slab information.

3D Vein Matching for Complex Project Layouts

The D2 Iris Scanner is fully compatible with Match 3D software, enabling detailed visualization and layout planning directly from the scanned slab images. Whether you’re preparing a bookmatched wall, a waterfall countertop, or continuous pattern flooring, the system allows you to align veining with precision and present finished project mockups to clients with full confidence.

-

Drag-and-drop slab layout tools

-

Supports bookmatching, miters, and flow-through applications

-

Compatible with Slabsmith and other industry-standard programs

This visualization capability not only improves internal efficiency but can also help close sales by offering clients a clear view of how their selected slabs will come to life.

Automatic Labeling and Intelligent Measurement

Immediately after a scan, the system calculates slab dimensions and outputs a printed label containing relevant material data. This eliminates the need for manual measurements and ensures every slab is accurately cataloged and easily identifiable on the shop floor.

-

Automatically detects slab length and width

-

Customizable label formats

-

Reduces labeling errors and improves traceability

Smart Design for Today’s Fabrication Shops

Unlike traditional flatbed photography stations, the D2 Iris Scanner features a vertical design that minimizes its footprint—saving valuable floor space without sacrificing functionality. Its dual pneumatic pistons provide safe and easy slab unloading, and the 22” HD touchscreen interface makes it easy for operators to navigate, zoom in, or mark up slab images for review.

-

Compact footprint: requires only one-third the space of standard systems

-

22″ glass touchscreen for fast interaction and training

-

Easy for teams of all sizes to adopt into daily workflow

-

Pneumatic unloading protects both slabs and operators

Specifications

| Image Resolution | up to 12K |

| Scanning Area | 151″ x 85″ |

| Scanning Time per Slab | ~ 16 seconds per slab |

| System Compatibility | Works with Match, Slabsmith, and other slab imaging platforms |

| Interface | 22″ HD multitouch glass screen |

| Number of Cameras | 2 |

| Structure | Galvanized steel for durability |

| Power Requirements | 110V / 240V |

| Unloading | Dual Pneumatic Pistons |

| AI-Driven Smart Features | Integrated AI supports slab recognition, defect detection, and automated tagging—speeding up processing and improving accuracy across your workflow. |

| Lighting Control | Internal LED lighting ensures consistent, shadow-free scans regardless of external shop lighting conditions |

| Machine Footprint | 16′ x 6′ 3″ x 9′ 5″ |

| Weight | 2,755 lbs |

Why Choose Northwood Machine for Your D2 Iris Scanner?

As a trusted partner in the stone fabrication industry, Northwood Machine provides not only access to world-class technology like the D2 Iris Scanner, but also the support, guidance, and integration experience needed to ensure long-term success. Our team works closely with shops to assess workflow needs and recommend smart additions that boost productivity, accuracy, and customer satisfaction.

Want to See the D2 Iris Scanner in Action?

Reach out to our team to schedule a virtual demo or request more information. Whether you’re considering your first digital imaging system or looking to upgrade an outdated solution, the D2 Iris Scanner offers next-level performance in a compact, intelligent design.