Northwood’s GW-128 Glass Router is a low-profile, horizontal-bed glass machine that gives you the flexibility and power to tackle almost any architectural glass project. The easy-to-use machine interface and industrial control, combined with industry leading CAM software, will have your shop creating beautiful glass panels, table tops, and artwork you never thought possible – and, will help you do so with less labor and higher precision than your competition.

GLASS EDGING, ROUTING, AND DRILLING APPLICATIONS

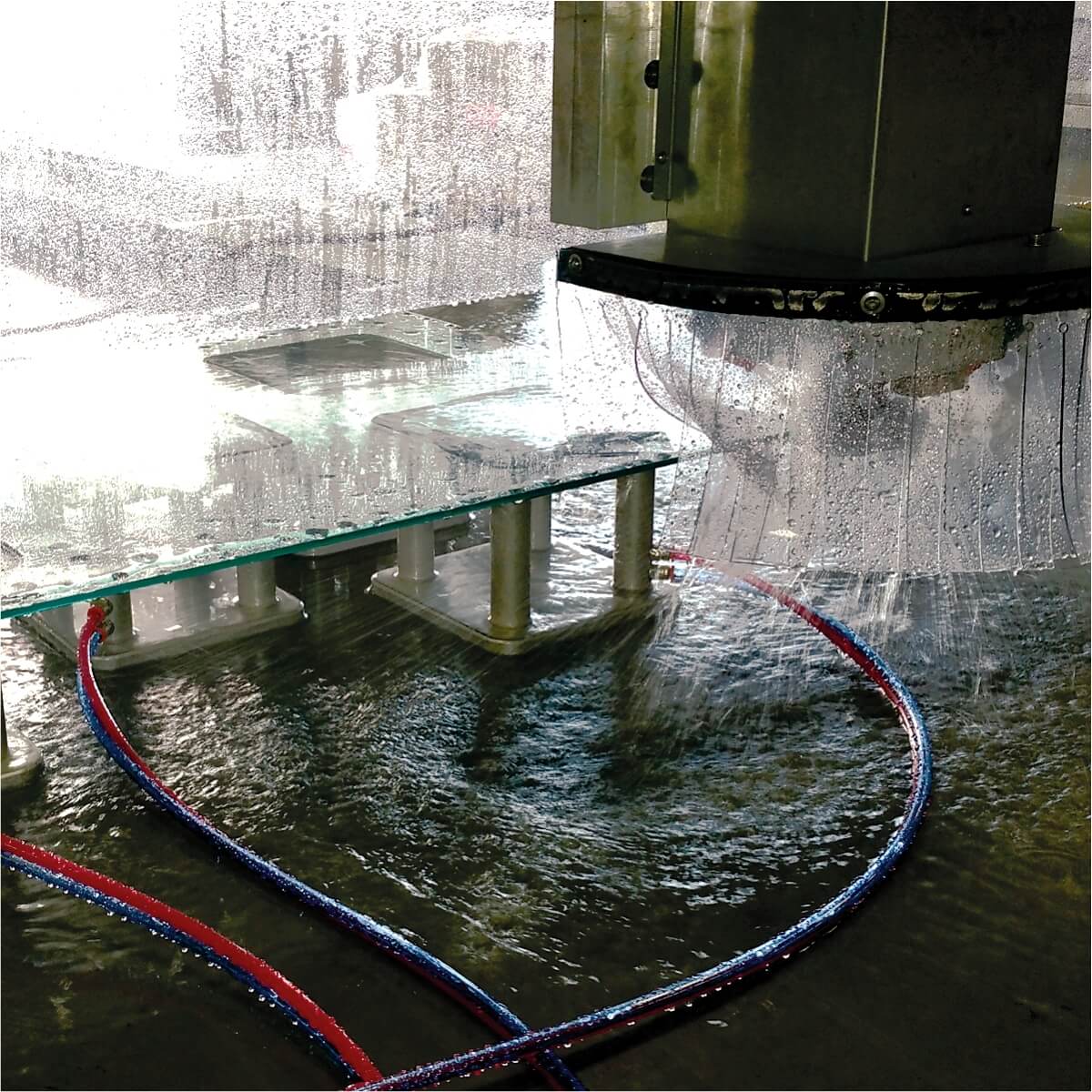

Northwood CNC Glass routers are capable of glass showers, furniture, and architectural glass for residential applications. For commercial applications, Northwood CNC machining centers are used for glass escalators and aerospace applications of glass up to 1 inch thick. Northwood offers both exterior natural water halo coolant as well as thru the cool coolant. CNC Tooling is available to accommodate hardware cutouts, grooves, and edging.

Features and Benefits

AUTOMATIC TOOL CHANGER & LASER CALIBRATION

Northwood provides a fixed-position Automatic Tool Change System to accommodate necessary tooling for edging glass. The machine comes with Laser-Calibration for tools to ensure the best-in-class machining. The durable composite table provides for universal Vacuum Pod Location on the table with Manifold Distribution and remote control, standard. For even faster setups, an automatic overhead laser project system (optional) can project the location of either vacuum pods, stops, or cups, and the cut path of the CNC Machine.

FANUC® CNC MOTION CONTROLS & BALLSCREW DRIVES

FANUC® is one of the most respected and widely used digital servo control systems in the motion control industry. The FANUC® drive system coupled with precision ground ball screw drives are designed to carry immense loads with unbelievable precision. The 40mm ball screws are designed to provide years of trouble free operation with simple maintenance and zero adjustments. This high level of accuracy on the finished parts is the “Northwood Difference.”

Extreme Duty Spindle “EDS”

- Constructed of corrosion-proof 100% Stainless Steel

- Spindle and motor are separated eliminating heating of bearings

- Reliable 20HP FANUC Servo Motor with built in cooling

- Direct drive delivers more torque at a greater range of speeds to the tool tip

Industry Leading Controls

When heavy duty CNC machinery is combined with Northwood’s Glass Fabricator Interface™ and the easy-to-use Glass Machine Control™, the new, Northwood GW-128 brings World Class horizontal-machining of glass to the modern fabricator! This includes Tool-Wear Compensation, Automatic Tool Management with Barcode, and tethered MPG Unit Control.

Northwood Parts and Service

Located in Louisville, KY, Northwood is centrally located in the US. Factory Direct technicians as well as regional support through factory certified technicians are available throughout North America. Our technical support staff is geared towards keeping your machinery running productively. Training is provided on-site at your facility to get real-work application experience. Finally, most parts are available for overnight delivery direct from the factory.