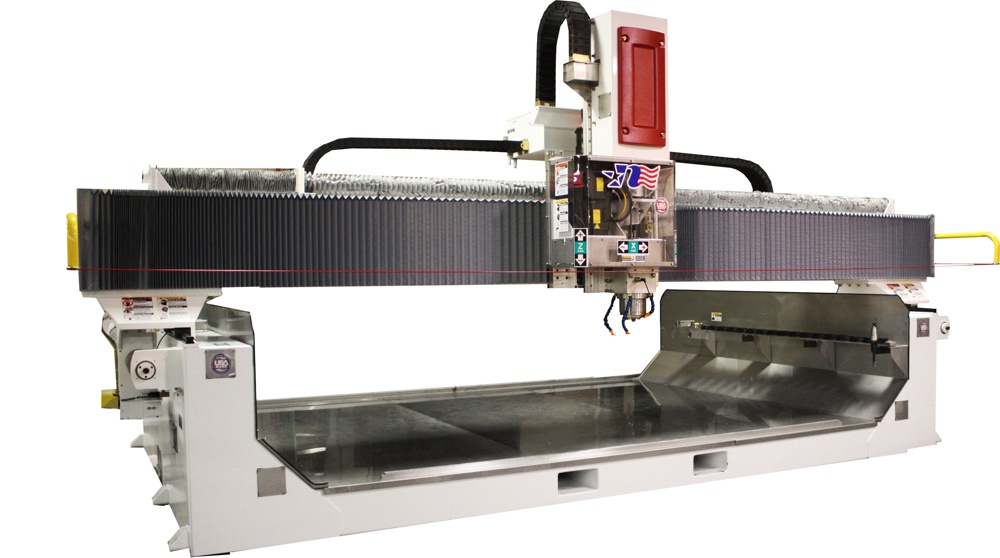

Northwood Vertical Bridge Mill is used in the Stone, Glass, and metal working applications that require flood coolant. The 20HP Fanuc driven spindle options include ISO40 taper as well as ISO50 taper allowing for larger tooling. Thru-the-Spindle tool coolant as well as external halo coolant is utilized to cool the tool tool. Static automatic tool changer racks as well as dynamic travel along automatic tool changers are available. This machine is shown above with 30″ (762mm) Z-Ram, but Northwood can accommodate smaller or larger Z-Axis as required for the application. Northwood never forces the customer to use an existing machine design, but instead customizes a machine for each unique application.

Vertical CNC Mill Industries

Aerospace – The accuracy and precision of Northwood CNC Machining Centers has surpassed the needs of many aerospace companies. Northwood has provided years of reliable service to suppliers in the commercial aviation, business class, and private jet aircraft manufacturers.

Energy and Defense – In the Wind Energy Manufacturing industry, Northwood has designed custom products that serve in hi-end manufacturing environments

Stone and Glass – Northwood Stoneworks has machinery custom designed for the Stone Fabricator. This includes architectural millwork or building stone design.

Transportation – Northwood serves the Transportation industry in various ways. Companies in the automotive, marine, railway and recreational vehicle (RV) industries use Northwood Machining Centers to process parts that are critical to their manufacturing process.

Other Industries – Northwood has sold CNC Machining Centers to many other industries. Northwood doesn’t just build CNC Machining Centers that are made for only one application, but instead building a solid modular machining center that can accommodate many different tooling configurations.