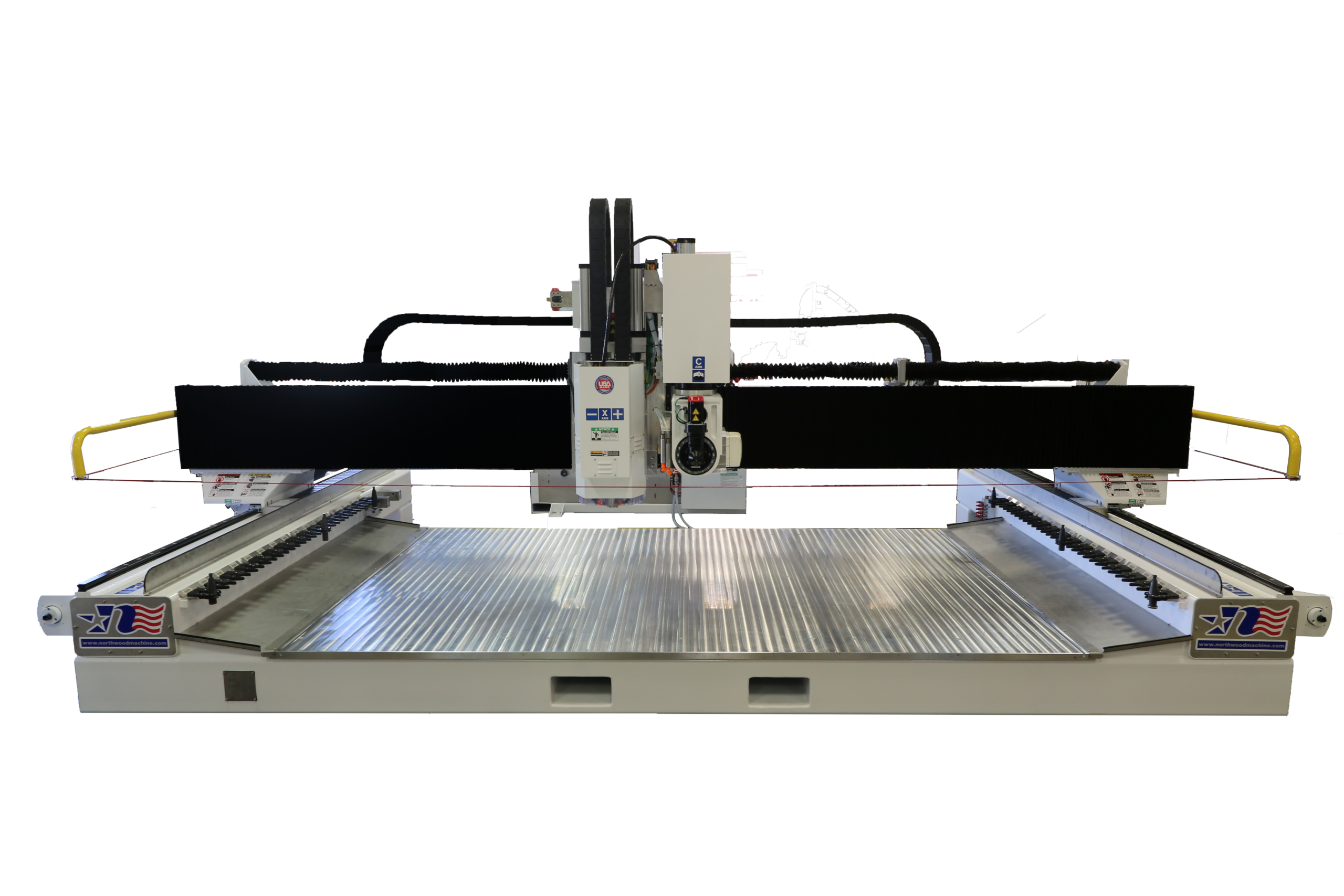

This model exceeds the challenging needs of most contemporary stone fabricators. The large work envelope (156″ x 96″) allows the operator to process an entire slab worth of countertops in one setup. The 138UFC has […]

With the introduction of the Fanuc Driven, Saccardo Sawing Motor, we raised the bar to a new level. In addition to applying 15hp to the blade, we now offer full mitering capabilities. You can now cut mitered edges from 44-91 degrees. Cutting slabs with speed makes the FabCenter the one machine choice.

Northwood introduced the Extreme Duty Spindle in 2006. Unlike the commonly used electrospindle, the EDS was engineered with stone fabrication in mind. The EDS design separates the motor from the spindle, ensuring a longer life with fewer repairs. This spindle design provides a huge amount of torque at low RPM. Leathering slabs will not overload the spindle. We are so confident in our spindle design that we offer a 3-year warranty.

Northwood introduced the 138 series in 2001. Since then we have improved and refined that design. From the EDS spindle with a 3-year warranty, ball screw drives, and Fanuc motion controls to incredible measures to ensure corrosion resistance and long machine life. This machine is a serious machine tool.

In 2007 Northwood revolutionized the stone industry by introducing the FABCENTER. This concept introduced the idea of a one-machine digital processing solution. You can cut slabs and mill them on the same machine. Since the initial introduction, Northwood has diligently refined and perfected the FabCenter. If you are looking for a one-machine solution or would like to add a CNC with a solid saw to your line up, the Northwood FabCenter is for you.

The 5th Generation Northwood FabCenter uses a 15HP direct-drive Saccardo Sawing Motor. This tilt function uses a Fanuc Servo to tilt from 44-90 degrees. This saw cut the slabs quickly and efficiently utilizing Northwoods Smart Saw technology.

A sawing solution you can count on.

Northwood introduced the Extreme Duty Spindle in 2006. Unlike the commonly used electrospindle, the EDS was engineered with stone fabrication in mind. The EDS separates the motor from the spindle and preventing expensive rebuilds that are so common in the world of electrospindles. This spindle design provides a huge amount of torque at low RPM. Leathering slabs will not overload the spindle. We are so confident in our spindle design that we offer a 3-year warranty.

This model exceeds the challenging needs of most contemporary stone fabricators. The large work envelope (156″ x 96″) allows the operator to process an entire slab worth of countertops in one setup. The 138UFC has […]

The 158UFC was designed from the ground up for the modern stone fabricator who desires an even bigger machine. With a massive work envelope of 180″ x 96″ and the same quality machine components as […]

Architectural Millwork or Building Stone Machining Centers The Northwood 138-AM Router for the Architectural Millwork industry was designed with the same EDS (Extreme Duty Spindle) technology, but with 30″ of Z-Stroke. The machine is specifically […]