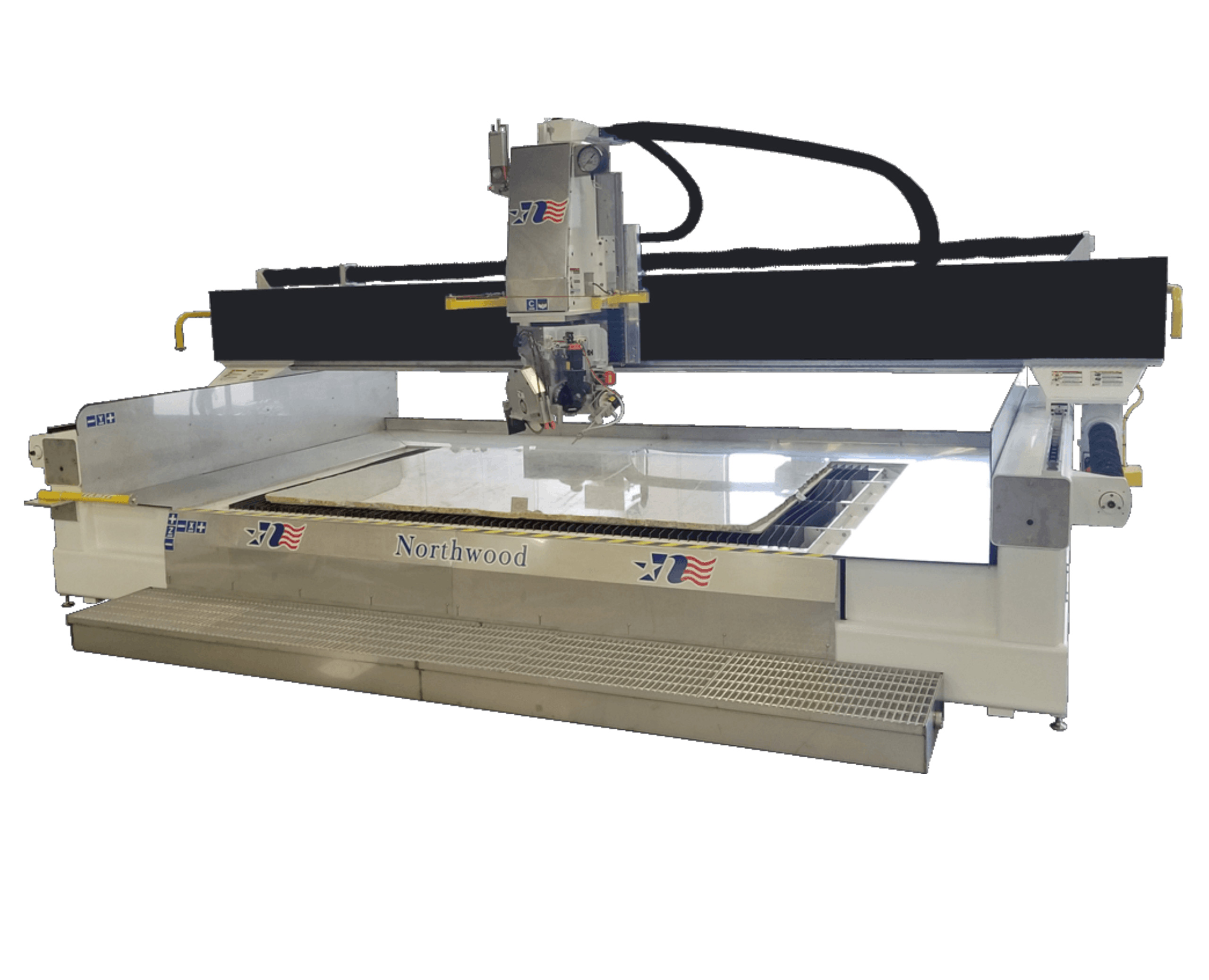

5-Axis CNC Sawjet for Saw, WaterJet, Saw Miter Cuts and WaterJet Miter Cuts

SERVO MITRE SAW

The SawJet comes with a 32 HP Saccardo motor and 18″ blade for cutting marble, granite, and limestone. The saw is equipped with Smart Saw Feed Function that uses dynamic force feedback to continuously vary cutting speeds, this allows for improved efficiency when cutting quartz and Dekton(TM) stone products. Mitering capabilities through the Nabtesco gearbox and Fanuc drive allow up to 48 degrees of motion.

KMT Pump and Garnett System

In addition to the saw-motor, the Saw Jet is equipped with an abrasive waterjet head from KMT Waterjet, and is powered by a 60,000 PSI Intensifier Pump. The garnet is fed from a pressurized reservoir to a motor-driven, metered feeder system proximate to the waterjet nozzle. The SawJet software automatically switches between the saw and waterjet as the condition demands and blends the two cuts as a product of an easy-to-follow calibration routine. In addition, Northwood’s industry-leading StoneVision(TM) 3.0 software, coupled with Alphacam(TM) software by Hexagon Manufacturing Intelligence, takes the difficulty and risk out of processing drawings or digitized data into machine toolpaths.

The SawJet integrates a complete run of high-pressure stainless steel piping. The piping lines are contained in a dual-chamber energy chain, providing proper protection and control of each line. This system improves the life and reliability of the hp pressure lines.

Fanuc Servo Driven Ground Ball Screws

The SawJet is controlled by a FANUC Servo control system closely integrated with a 40mm ground ballscrew This combination is designed to provide years of trouble-free operation and also provide the highest level of accuracy. Northwood’s interface software and machine control allows an operator to quickly load and run part programs, as well as perform other machine tasks. In addition, Northwood’s industry-leading StoneVision(TM) 3.0 software, coupled with Alphacam(TM) software by Hexagon Manufacturing Intelligence, takes the difficulty and risk out of processing drawings or digitized data into machine toolpaths.

Large Interface makes Programming Easier

The 21.5″ widescreen, touch display makes programming jobs even easier, using our industry-leading software, performance hardware and the security of Windows 10.